AIR SANITATION

·

Air sanitation is a process of control of

microorganisms in air.

·

Air sanitation is the system of removing the

impurities present in air inside buildings to protect people from infections.

·

Sanitation of air is essential in enclosed

places like

ü Hospital wards

ü Operation theatres

ü Burns unit

to prevent infection

ü Food processing

and packaging industries

ü Rooms where

sterile materials or products are stored require aseptic atmosphere.

DEVICES USED

FOR AIR SANITATION

1) Ventilation

·

Ventilator is an opening or a device that

allows fresh air to enter into an enclosed space.

· A great

reduction in the airborne microorganisms can be brought about by laminar

airflow system developed by Whitfield.

· It was found

that a horizontal flow of air at about 40 feet/minute in a room in which spores

of Bacillus subtilis had been liberated, led to a diminution in their

numbers by 100—1000 times greater than that to be expected in a room where

turbulent ventilation was employed.

·

The ultimate criterion of its effectiveness

must be the diminution of cross infection.

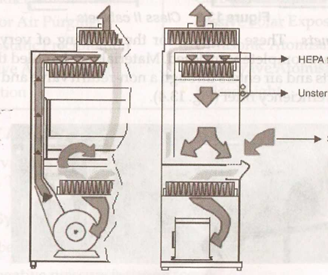

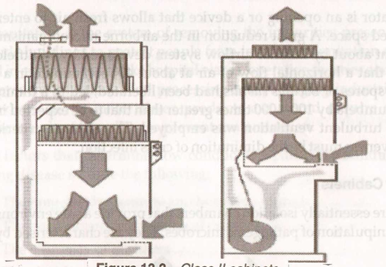

2) Safety

Cabinets

· Safety

Cabinets are essentially isolation chambers that provide a safe environment for

the manipulation of pathogenic microbes.

·

Safety Cabinets are characterized by having

considerable negative pressure air flow that provides protection from

infectious bio-aerosols generated within the cabinets.

· Safety

Cabinets are of three classes.

Class I Exhaust protection cabinets

They protect the operator by maintaining a rapidly moving stream of air, which entrains infectious particles and deposits them on a high efficiency filter. The air is then discharged outside the building.

These are open-fronted and are designed to protect the material that is being handled from extraneous contamination. It is suitable for most work with moderate pathogens. They do not protect the operator, though they can be modified to do so.

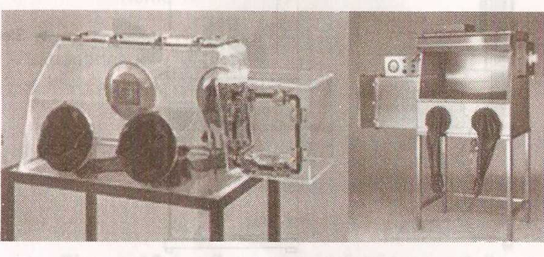

Class III cabinets

These are used for the handling of very

dangerous materials and are completely enclosed. Materials are handled through

gastight glove ports and air enters through a non-return valve and is extracted

through a high-efficiency filter.

AIR SANITATION

METHODS

1)

Filtration of Microorganisms

·

High Efficiency Particulate Air Filter (HEPA)

filter will filter micron sized particles at about 95 % efficiency.

· HEPA filters

are Box type filters or Bag type filters.

a) Box or Pleated

type HEPA filters can be as thin as 2 - 4 inches, or as wide as 8 - 12 inches.

b) Bag type

HEPA filter, which can extend upto 24 inches.

· Bag type

filters typically have a lower pressure drop than the Box type HEPA and are

more efficient.

· HEPA filters

are typically rated as 99.97 % effective in removing dust and particulate

matter.

· HEPA filters

have effective pore sizes of 0.3 µm, small enough to capture Bacterial cells,

Endospores and many viruses, as air passes through these filters, nearly

sterilizing the air on the other side of the filter.

·

HEPA filters are commonly found in Hospital

isolation rooms, Operating theatres, Pharmaceutical manufacturing units and

Industrial clean rooms.

2)

Ultraviolet Germicidal Irradiation (UVGI)

·

Microbes are uniquely vulnerable to the effects

of light at wavelengths at or near 260 nm due to the resonance of this

wavelength with molecular structures.

· Ultraviolet light

possesses just the right amount of energy to break organic molecular bonds.

This bond breakage translates into cellular or genetic damage for microorganisms.

The same damage occurs to humans, but is limited to the skin and eyes.

·

Viruses are especially susceptible to UVGI

more than bacteria.

3)

Fumigation with Disinfectants

·

Fumigation is an effective form of

disinfection, as gas can spread rapidly within the space to be disinfected, and

all the hidden corners and blocked surfaces.

· The disinfectant

is vapourized (by heating or boiling) into fine droplets using a

fogger and blown into the air. Upon settling down, these droplets reveal

their effect.

· Formaldehyde

fumigation has long been an accepted method for areas where microbiological cleanliness

is required.

·

Vaporized Hydrogen peroxide is a dry gaseous

method that has been used as a reliable alternative for Formaldehyde.

Comments

Post a Comment